Latest Facts and News

- Digital printing technologies revolutionise camo pattern production.

- Eco-friendly camo printing methods have gained popularity in the textile industry.

- Fashion designers incorporate unconventional camo prints in recent collections.

- Advanced camo patterns developed for urban and digital environments

Do you know what once helped soldiers blend into the wild is now making bold statements everywhere? Camo is now a bold, stylish way to bring life to your wardrobe, home or brand!

Our premium camo prints are crafted with vibrant colours, durable materials and detailed patterns, perfect for your next creative project. Whether you’re upgrading your wardrobe, refreshing your decor or giving your brand a bold twist, camo prints are the statement you didn’t know you needed till now.

Read along to learn more about the techniques, materials and innovative designs in camo printing…

The Evolution of Camo Printing

Camouflage was first created in France in 1914 by artist Lucien-Victor Guirand de Scévola and a team of painters. They used their skills to help hide soldiers, equipment and movements by making them blend into the surroundings, starting the idea of military camouflage.Over the years, camouflage pattern printing has grown from a wartime necessity into a creative design embraced by artists and architects and a staple in the fashion world.

Did You Know?

During World War II, Australia’s camouflage efforts were so innovative that they created patterns specifically designed to blend with shadows and light unique to the landscape. Led by a zoologist, William Dakinand, and a team of artists, they even faced resistance from the military but still managed to change how camouflage was used!

What is a Camouflage Print?

Camouflage print originated in the mid-18th century when rifle units were issued green, brown and earth tones uniforms to blend into natural environments. Since then, countries have created their distinctive camouflage designs, using specific colours and patterns to suit their local terrains and operational needs.

Camo Printing Techniques

Camo printing has grown to suit different industries, mixing traditional methods with modern ideas.

Traditional Printing Methods

Techniques like screen printing and rotary printing have been widely used to produce consistent, high-quality patterns on fabrics and other materials.

- Screen Printing: This technique involves pushing ink through a mesh screen onto a substrate, allowing for precise layering of colours. It is ideal for large-scale production of camo patterns with sharp and detailed designs.

- Rotary Printing: Often used for fabric rolls, rotary printing employs engraved rollers to apply camo patterns continuously. This method is one of the common military print techniques that ensures uniformity across long stretches of material.

Digital Camo Printing

Digital camo printing represents the future of camouflage design, combining advanced technology with creative flexibility. Unlike traditional methods, digital printing uses specialised printers to apply intricate custom camo patterns directly onto materials, offering several advantages:

- Customizable Patterns: Digital printing allows intricate, unique designs with endless creative possibilities, from bold colours to abstract patterns.

- Quick Turnaround: No screens or rollers needed, speeding up production for small batches and one-time projects.

- Eco-Friendly Options: Uses water-based inks and reduces waste, offering a sustainable alternative to traditional methods.

- Precise Results: Delivers clean, sharp and consistent patterns for standout designs.

- Flexible for Any Scale: Works perfectly for both single items and large collections.

Some other camo printing techniques include:

Dye Sublimation for Fabrics

Heat transfers dye directly into the fabric, creating vibrant, long-lasting camo patterns. This method works best on polyester and synthetic blends, ensuring colours won’t fade or peel. It’s ideal for clothing, flags and outdoor gear.

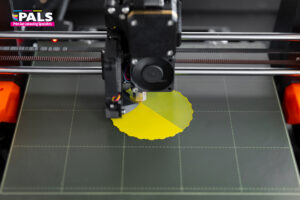

3D Printing of Camo Textures

3D printing allows for the creation of raised camo textures on various surfaces, adding depth and realistic designs. It is commonly used for military gear, accessories and even architectural elements.

Check this out: Professional Printing Services for All Business Needs

Materials and Fabric for Camo Printing

When it comes to camo printing, choosing the right materials and fabrics is essential to ensure durability, vibrant patterns and functionality for various applications.

Camo Bullet Fabric

Bullet fabric or Bullet Liverpool, is a medium-weight material with a smooth front and textured back, made from polyester and 4–5% spandex. Its two-way stretch and durability make it perfect for jackets, dresses, tops, skirts and accessories. Camo patterns add versatility, making it a popular choice for stylish, low-maintenance camouflage apparel.

Camo Techno Fabric

Techno fabric, made from polyester with spandex, is lightweight, stretchy, water-resistant and durable. Ideal for industrial and military clothing, its camo designs suit activewear, shoes and household items. Its strength and flexibility make it both practical and versatile.

Camo Melton Fabric

Melton fabric is a thick, warm wool blend known for its smooth finish and durability. Traditionally used in military wear, camo Melton is now favoured for winter coats, jackets, suits and warm accessories like scarves and hats, offering style and cold-weather protection.

Fibres, Dyes And Applications in Camouflage Printing

For optimal camo printing results, selecting durable fabrics such as cotton, canvas or blends is essential. These materials effectively absorb dyes, ensuring vibrant and long-lasting camouflage patterns.

| Material | Dye Type | Applications |

| Polyester | Disperse carbon black | Lightweight, durable items like nettings, sleeping bags, tents, webbing and belts. |

| Nylon | Acid, metal complex, carbon black | Rain gear, carrying systems, combat suits, webbing and hook-and-loop fasteners. |

| Nylon/Cotton | VAT dyes, carbon black | Combat suits combine cotton’s breathability with nylon’s durability for comfort and functionality. |

| Special Fibres | Pigments | Fire-retardant netting, Aramid fibre combat suit and specialised items for extreme conditions. |

When in confusion, let Print and Laminating Specialists (PALS) guide you to the perfect fabric to ensure your camo designs look sharp and last long.

Applications of Camo Printing

Camo printing has evolved from its military origins to find applications across various industries. Here’s an overview of its diverse uses:

Military Use

As you already know, Camo printing is crucial for hiding personnel, vehicles and equipment in operational environments. Forest patterns provide cover in wooded areas, desert designs are tailored for sandy terrain and urban camo blends into cityscapes. Modern techniques like digital printing add features such as infrared reflectance control to evade night vision detection.

Fashion and Style

Camo has become a staple in clothing, especially in jackets, cargo pants and streetwear, offering a rugged yet fashionable look. Accessories like bags, caps and footwear also feature camo, combining style with a utilitarian edge.

Home Décor

Camo patterns enhance interiors by adding a bold, adventurous vibe. Popular in upholstery, bedding, curtains and throw pillows, camo is used to create themed rooms or statement pieces.

Outdoor and Hunting Gear

Camo printing is essential for reducing visibility during hunting or wildlife observation. It’s commonly applied to jackets, pants, gloves, backpack and tent fabrics, ensuring seamless blending into natural environments.

Automotive Customization

Camo wraps and paint are widely used for off-road vehicles, motorcycles and utility trucks. These designs provide a unique aesthetic and practical camouflage for outdoor activities like hunting or expeditions.

Check out: Stationery Printing

The Future of Camo Printing

Camo printing has come a long way from its original purpose of blending into surroundings. Today, it combines traditional camouflage elements with modern art and technology, making it versatile and visually appealing across industries.

- Abstract Camo Patterns: These designs use irregular shapes, gradients and creative colour schemes. Popular in fashion and branding, they give a fresh and stylish twist to classic camo.

- Digital-Inspired Designs: Pixelated and geometric camo patterns offer a sleek, modern look. Created for military use, they’re now a hit in tech-inspired fashion and urban streetwear.

- Unconventional Colours: Bold shades like neon, pastel and metallic make camo stand out in creative industries. These vibrant designs allow for personal expression and unique style.

Concluding Thought

Camo printing has embraced sustainability with eco-friendly practices, including water-based inks and recycled materials, catering to environmentally conscious consumers.

Its durability and adaptability ensure it remains a timeless option, whether for blending into natural surroundings or making bold, creative statements in fashion, decor or industrial design.

Simple Tips to Care for Camo Prints:

- Wash gently with mild detergent.

- Air dry to keep colours bright.

- Avoid long exposure to sunlight to prevent fading.

To know more, get in touch with PALS.

FAQ

1. What are the most popular camo printing patterns?

The most popular camo patterns include Woodland, for forest environments; Desert, for arid landscapes; Urban, designed for cityscapes; Digital, with pixelated designs for modern military use; and Multicam, known for its versatility in varied terrains.

2. How does digital camo printing differ from traditional methods?

Digital camo printing uses advanced technology to create highly detailed, customizable patterns directly on the fabric. Unlike traditional methods like screen printing, digital printing doesn’t require screens or stencils, allowing for more intricate designs, faster production and less material waste.

3. Can camo printing be done on any type of fabric?

Camo printing can be applied to most fabrics, but the results depend on the material. Natural fabrics like cotton and blends absorb dyes well, while synthetic materials like polyester may require special inks or treatments. Some fabrics, such as stretch blends, are preferred for durability and versatility.

4. Are there regulations for using military camo patterns in civilian products?

Yes, many countries regulate the use of official military camouflage patterns to prevent misuse and maintain exclusivity for armed forces. Civilian camo designs often use modified or abstract versions of military patterns to avoid infringement and ensure compliance with legal standards.

5. How has camo printing influenced modern art and design?

Camo printing has had a significant cultural impact, symbolising rebellion, individuality and style. It has inspired streetwear, high fashion and even interior design, blending utility with creative expression. Artists and designers often use camo patterns to challenge traditional norms and create bold, eye-catching statements.